Overview

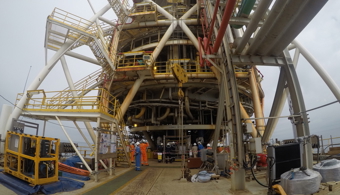

James Fisher Maritime transport, part of James Fisher & Sons PLC were challenged to provide an SME testing and wireless load monitoring solution to support the safe transport of 60 heavy-duty petrochemical modules for our customer Mammoet. The project required precise and reliable technology that would support the demanding timeframe while ensuring safe heavy lifting operations.

The Challenge

James Fisher Maritime transport were engaged by heavy lifting and transportation specialist Mammoet to provide a comprehensive and tailored load monitoring solution to support the transit of 60 modules, ranging from 30 to 175 tonnes, for a major furnace shipment project in Maine, USA. The company required a technology that would provide accurate weight verification for each module to enable efficient loading and shipping. Wireless load cells were essential to remove trip hazards, reduce set-up time and ensure safe heavy lifting operations.

Solution

The James Fisher Maritime transport team developed and manufactured 25 COG (centre of gravity) load cells offering precise, real-time load monitoring rated to 200% of load, which would effectively accommodate the weight range involved. The wireless design eliminated risks associated with cables including slips, trips, and falls, helping to safeguard personnel throughout the process. A custom-built software solution enabled seamless integration with Mammoet's existing configuration, ensuring a full turnkey solution for heavy lifting.

Our Impact

The most valuable thing this project brought to Mammoet was the minimised risk to personnel, eliminating risks associated with cables including slips, trips and falls, while the bespoke wireless load monitoring solution enabled project completion ahead of schedule, within budget and without incident. The load cell technology the team provided with wireless capability offered Mammoet precise, real-time load monitoring, helping to reduce set-up time and supporting the very challenging 10-month delivery schedule. Today Mammoet continues to use this technology for similar projects.

Tjitske van Schelven, Project Engineer, Mammoet USAFrom start to finish, James Fisher was professional, responsive and highly capable. Having never used wireless load cells before, we were pleased that this technology was able to deliver time savings that played an important role in project’s on-time completion. We were also impressed with its team’s flexibility in meeting our implementation requirements, as well as with the overall accuracy and reliability of its solution.

More case studies

Read article

Read article

Dive tank demonstration for internal cut and lift technology

Read article

Submarine hull tests at National Hyperbaric Centre

Read article

Greater Gabbard turnkey operations and maintenance

Read article

Remote ROV audits for Heerema Marine

Read article

Cable-stayed bridge structural health monitoring solution

Read article

Testing monitoring system to restore FPSO production

Read article

SME testing support for heavy lifting operations

Read article

Annual Report 2024

Annual Report 2024