Overview

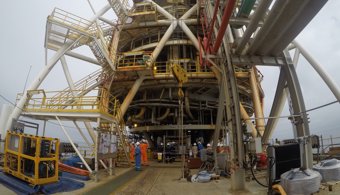

JFD, part of James Fisher and Sons plc., has successfully performed a hydrostatic pressure test on subsea cables for a customer conducting subsea support operations. Tests were conducted at the company’s National Hyperbaric Centre facility in Aberdeen, Scotland, maintaining strict adherence to safety protocols and ensuring full quality assurance through an innovative remote witnessing process. By leveraging cutting-edge technology the customer and third-party accreditation body were able to validate the test in real-time, significantly reducing costs and ensuring compliance with industry standards.

Challenge

As part of subsea support operations our customer required hydrostatic pressure testing of cables to meet industry quality assurance (QA) requirements. The primary challenge was to conduct the test safely while adhering to pandemic safety protocols while facilitating remote witnessing by an independent accreditation body to ensure that the validation process met strict regulatory requirements. With travel and site restrictions making traditional methods of witnessing impossible the solution needed to meet technical standards while mitigating witness risk.

Solution

State-of-the-art testing facilities at the National Hyperbaric Centre were used to conduct the hydrostatic pressure test on subsea cables, at 50 PSI in a 100-bar chamber simulating the real-life subsea pressure conditions that the cables would experience during operational use. To prove the veracity of the qualification a live stream from the testing facility enabled customer and independent classification body, Bureau Veritas, to witness the test remotely. Real-time data and live results were streamed via the remote setup allowing the test to be verified without third-party accreditors being physically present. This approach met strict pandemic safety measures and provided a cost-effective solution for the customer.

Value to customer

- By eliminating the need for travel and on-site personnel the customer was able to reduce the overall costs associated with the test process

- JFD’s remote witnessing approach followed all necessary safety measures, to ensure the health and safety of personnel.

- Remote witnessing allowed the test to be completed efficiently without compromising stringent QA and industry standards required by the classification body.

- The customer was able to witness the test remotely, ensuring complete transparency in the testing process and confidence in the integrity of their subsea cables.

More case studies

Read article

Read article

Dive tank demonstration for internal cut and lift technology

Read article

Submarine hull tests at National Hyperbaric Centre

Read article

Greater Gabbard turnkey operations and maintenance

Read article

Remote ROV audits for Heerema Marine

Read article

Cable-stayed bridge structural health monitoring solution

Read article

Testing monitoring system to restore FPSO production

Read article

SME testing support for heavy lifting operations

Read article

Annual Report 2024

Annual Report 2024