Overview

JFD plays a pivotal role in ensuring that the NATO submarine rescue system (NSRS), which sits at the forefront of submarine rescue technology, is always prepared for rapid deployment. JFD operates and manufactures NSRS system equipment and delivers the advanced features, including transfer under pressure (TUP) capabilities and submarine decompression facility, that set the NSRS apart.

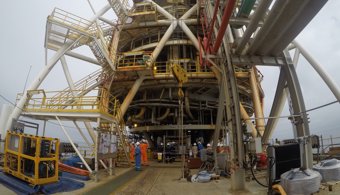

Submarine rescue vehicle deployment

Challenge

To maintain the NSRS in a constant state of readiness for NATO partner nations, France, Norway, and the UK, JFD regularly participates in submarine rescue exercises alongside NATO. These exercises help to demonstrate the capabilities of the NSRS intervention remotely operated vehicle (IROV). Features such as full air mobility and innovative fly-by-wire remote control technology allow rapid transfer of the system by rail or road, and significantly reduce deployment time to a mother ship (MOSHIP).

Submarine mating

Transfer of submariner to Transfer Under Pressure System

Solution

JFD helped to showcase the comprehensive rescue capabilities of the NSRS while adhering to safety standards and training additional personnel as required from its broad network of qualified and experienced professionals, which is key readiness and agility of the system. The JFD team provided life support equipment and designed and installed an automated control system to manage the rescue operation, helping the NSRS to retain its position as a world-leading facility in submarine decompression and rapid deployment.

The JFD cutting-edge transfer under pressure (TUP) system enables movement of personnel from a distressed submarine to a decompression chamber without exposing them to the risks of surfacing too quickly. The NSRS system has a 72-man recompression facility offering enhanced submarine decompression capability and full air mobility to enable rapid deployment in the event of a distressed submarine.

JFD manages the NSRS asset management programme and strategy to deliver robust maintenance with minimal downtime, to support asset availability. The company manages all maintenance activities, including hiring, vetting and monitoring third-party contractors as required.

The NSRS is monitored 24/7 from the JFD control centre, equipped with state-of-the-art marine management system (OWMS) to ensure that outages are quickly identified and addressed and support rapid incident response.

Value to customer

JFD helped to showcase the comprehensive rescue capabilities of the NSRS while adhering to safety standards and training additional personnel as required from its broad network of qualified and experienced professionals, which is key readiness and agility of the system. The JFD team provided life support equipment and designed and installed an automated control system to manage the rescue operation, helping the NSRS to retain its position as a world-leading facility in submarine decompression and rapid deployment.

The JFD cutting-edge transfer under pressure (TUP) system enables movement of personnel from a distressed submarine to a decompression chamber without exposing them to the risks of surfacing too quickly. The NSRS system has a 72-man recompression facility offering enhanced submarine decompression capability and full air mobility to enable rapid deployment in the event of a distressed submarine.

JFD manages the NSRS asset management programme and strategy to deliver robust maintenance with minimal downtime, to support asset availability. The company manages all maintenance activities, including hiring, vetting and monitoring third-party contractors as required.

The NSRS is monitored 24/7 from the JFD control centre, equipped with state-of-the-art marine management system (OWMS) to ensure that outages are quickly identified and addressed and support rapid incident response.

More case studies

Read article

Read article

Dive tank demonstration for internal cut and lift technology

Read article

Submarine hull tests at National Hyperbaric Centre

Read article

Greater Gabbard turnkey operations and maintenance

Read article

Remote ROV audits for Heerema Marine

Read article

Cable-stayed bridge structural health monitoring solution

Read article

Testing monitoring system to restore FPSO production

Read article

SME testing support for heavy lifting operations

Read article

Annual Report 2024

Annual Report 2024